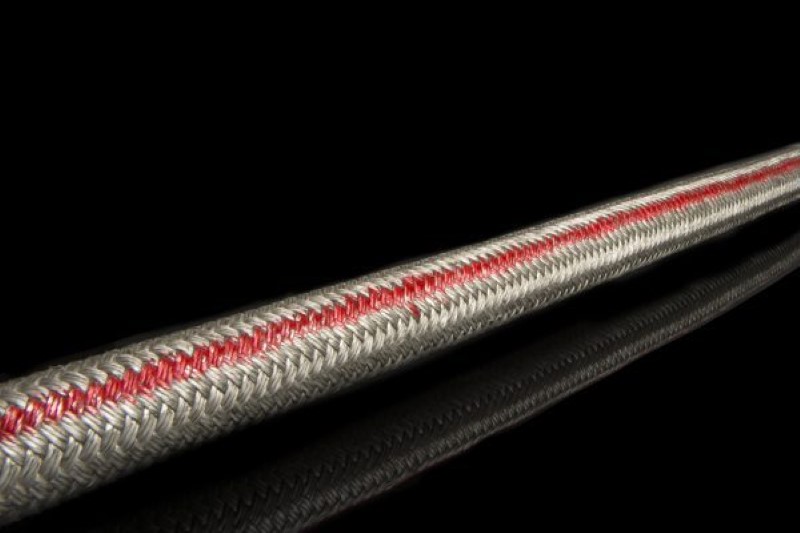

MAGNARO®-Twaron® Plus

Description

The MAGNARO®-Twaron® Plus rope is a custom-made mooring rope which is mainly selected to perform in very hot areas of the world. Conventional high performance ropes significantly lose strength around 50C and thus can be a health and safety breach in a mooring configuration. The The MAGNARO® Aramid ropes can withstand temperatures up to 427° C.

The US Marines has been using Aramid made mooring ropes for years, highlighting the technical proporties of Aramid. Aramid fibres are fully recycable and can be re-used to produce brake pads, bullet proof vests, helmets, tires, etc. TEHO supports a recycle program in which a used Magnaro Aramid mooring rope is bought back after its service life time resulting in reduced environmental footprint.

Features & Benefits

- Twaron® is Teijin Aramid’s flagship high-performance yarn

- High strength: excellent strength-to-weight ratio

- High dimensional stability with very low creep

- Long term rope durability because of Aramid’s unique chemical and mechanical properties

- Increased safety (low lash back)

- Cover gives extra protection against abrasion, increasing the rope’s service life

- Fully recyclable

Specification

| Dia. | Circ. | Weight | MBL (Unspliced) | MBL/LDBF*(Spliced) | ||

| mm | inch | kg/100m | Ton | kN | Ton | kN |

| 34 | 4 1/4 | 96.2 | 71.0 | 696 | 64.0 | 628 |

| 36 | 4 1/2 | 106 | 80.0 | 785 | 72.0 | 706 |

| 38 | 4 3/4 | 117 | 91.0 | 892 | 82.0 | 804 |

| 40 | 5 | 128 | 98.0 | 961 | 88.0 | 863 |

| 42 | 5 1/4 | 139 | 109 | 1,069 | 98.0 | 961 |

| 44 | 5 1/2 | 157 | 128 | 1,255 | 115 | 1,128 |

| 46 | 5 3/4 | 169 | 139 | 1,363 | 125 | 1,226 |

| 48 | 6 | 183 | 152 | 1,491 | 137 | 1,344 |

| 50 | 6 1/4 | 202 | 167 | 1,638 | 150 | 1,471 |

| 52 | 6 1/2 | 218 | 181 | 1,775 | 163 | 1,598 |

| 54 | 6 3/4 | 235 | 197 | 1,932 | 177 | 1,736 |

| 56 | 7 | 252 | 213 | 2,089 | 192 | 1,883 |

| 58 | 7 1/4 | 270 | 229 | 2,246 | 206 | 2,020 |

| 60 | 7 1/2 | 288 | 246 | 2,412 | 221 | 2,167 |

| 62 | 7 3/4 | 308 | 265 | 2,599 | 239 | 2,344 |

| 64 | 8 | 329 | 284 | 2,785 | 256 | 2,511 |

| *LDBF as per OCIMF MEG4 recommendations (spliced dry condition) | ||||||

Elongation

| Break Force | Elongation |

| 10% | 0.9% |

| 30% | 2.1% |

| 50% | 3.0% |

| 100% | 4.8% |

Certification

Our rope certification service is available upon request to provide you with peace of mind and confidence in your equipment. Our team of experts will perform a comprehensive analysis of each rope, using the latest testing equipment and techniques to evaluate its strength, durability, and overall suitability for use. This rigorous process will help you avoid potential problems and ensure the safe and reliable operation of your equipment. We can help you meet the various regulations and standards that apply to your equipment and provide you with the assurance that your equipment is up to the task. With our rope certification service available upon request, you can rest easy knowing that your equipment is safe, reliable, and optimized for performance.