35WxK7

Description

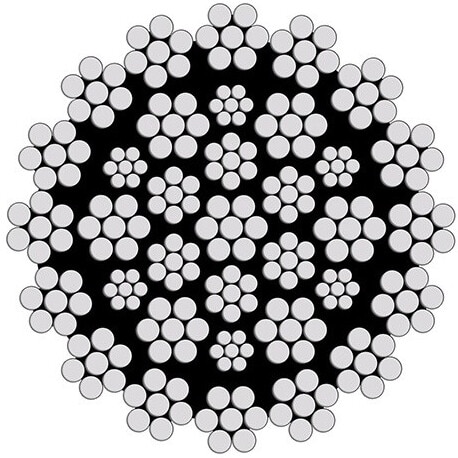

The steel wire rope 35WxK7 represents a formidable construction designed for exceptional strength and versatility. In this configuration, 35 wires are meticulously organized into 7 strands, with a Warrington-Seale construction (WxK7). This particular design enhances the rope’s flexibility while maintaining high tensile strength, making it well-suited for a diverse range of demanding applications.

The Warrington-Seale construction, denoted by “WxK7,” is characterized by a specific arrangement of wires in each strand, optimizing the balance between strength and flexibility. This results in a steel wire rope that excels in applications requiring both heavy-duty load-bearing capabilities and agility.

Renowned for its resilience against wear, corrosion, and challenging environmental conditions, the 35WxK7 steel wire rope is a durable solution for various industries. Its carefully engineered structure ensures smooth handling and efficient operation, making it suitable for lifting, rigging, towing, and other critical tasks.

Whether deployed in construction, mining, marine environments, or offshore operations, the 35WxK7 steel wire rope stands out as a reliable and robust choice. Its ability to withstand heavy loads while providing flexibility underscores its importance in applications where precision and strength are essential for successful and safe operations.

Specifications

TEHO SPECIFICATIONS

Weight: ISO Standard

MBL: ISO Standard

Tensile strength: 2160

Lay: Langs Lay

Lubrication: A-2

| Standard | Nominal rope diameter mm | Approximate nominal length mass kg/100 m | Minimum breaking force kN (2160 N/mm²) |

| ISO | 8 | ||

| 9 | |||

| 10 | 48 | 98 | |

| 11 | |||

| 12 | 68 | 140 | |

| 13 | 81 | 163 | |

| 14 | 94 | 192.5 | |

| 15 | 108 | 221 | |

| 16 | 127 | 250 | |

| 18 | 155 | 308 | |

| 20 | 198 | 394 | |

| 22 | 241 | 482 | |

| 24 | 284 | 572 | |

| 25 | 308 | 602 |

Certification

Our rope certification service is available upon request to provide you with peace of mind and confidence in your equipment. Our team of experts will perform a comprehensive analysis of each rope, using the latest testing equipment and techniques to evaluate its strength, durability, and overall suitability for use. This rigorous process will help you avoid potential problems and ensure the safe and reliable operation of your equipment. We can help you meet the various regulations and standards that apply to your equipment and provide you with the assurance that your equipment is up to the task. With our rope certification service available upon request, you can rest easy knowing that your equipment is safe, reliable, and optimized for performance.