4x36ws+FC

Description

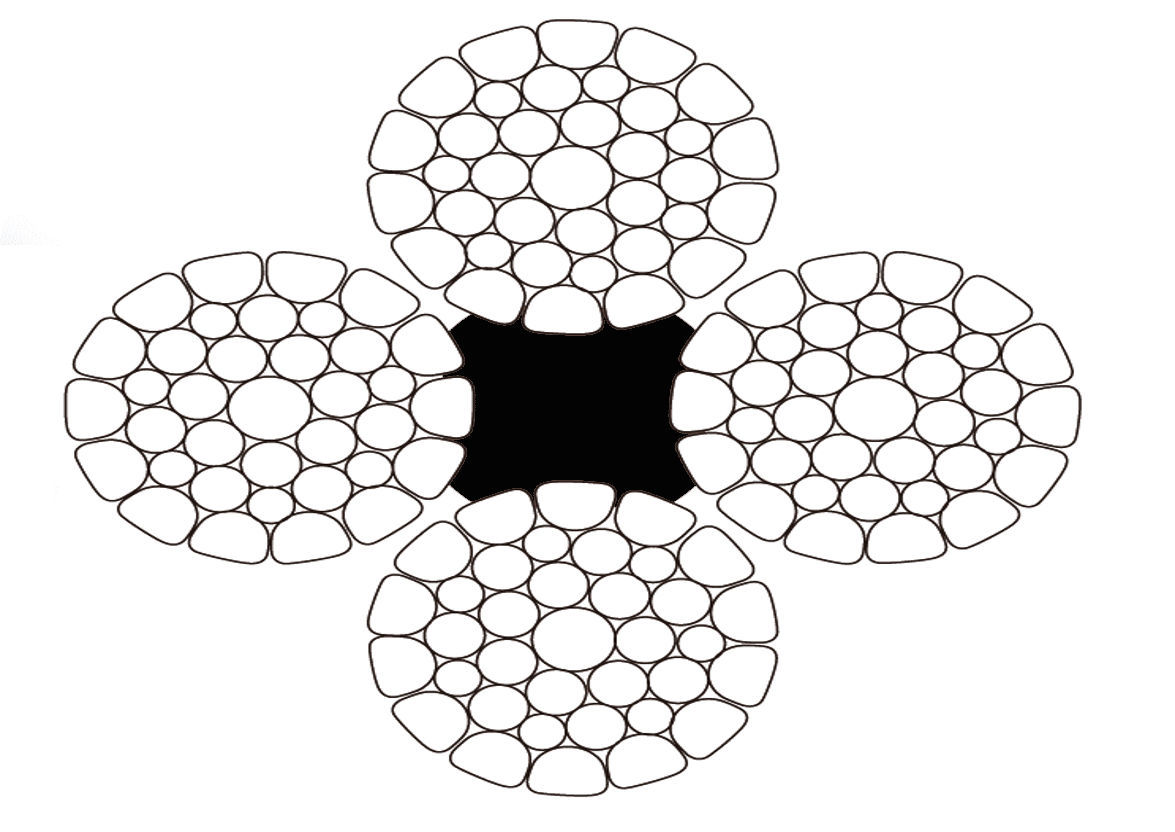

The steel wire rope 4x36ws+FC is a robust and versatile construction designed for optimal strength and flexibility. In this configuration, four main strands each contain 36 wires, and the rope is equipped with a fiber core (FC). This combination of strands and core enhances the rope’s performance in various applications, making it a reliable choice for lifting, rigging, and other heavy-duty tasks.

The 4x36ws+FC steel wire rope’s construction provides a balance between strength and flexibility. The four main strands, each consisting of 36 wires, contribute to the rope’s overall load-bearing capacity, making it suitable for applications where durability is essential. The fiber core further enhances flexibility and handling, ensuring smooth operation in various industrial settings.

Known for its resistance to wear, corrosion, and harsh environmental conditions, the 4x36ws+FC steel wire rope is a durable solution for demanding tasks. Its carefully engineered design allows for efficient handling and operation, making it well-suited for lifting heavy loads in construction, mining, and other industries.

Whether used in cranes, elevators, or towing applications, the 4x36ws+FC steel wire rope stands as a testament to reliability and performance. Its ability to maintain structural integrity under heavy loads makes it an ideal choice for applications where safety and durability are paramount.

Specifications

TEHO SPECIFICATIONS

Weight: Maker specs

MBL: Maker specs

Tensile strength: 1960

Lay: Ordinary/ Regular lay

Lubrication: A-2

| Standard | Nominal rope diameter mm | Approximate nominal length mass kg/100 m | Minimum breaking force kN (1960 N/mm²) |

| 12.5 | 103 | ||

| 18 | 120 | 225 | |

| 20 | 150 | 280 | |

| 22 | 188 | 345 | |

| 24 | 226 | 400 | |

| 26 | 256 | 470 | |

| 28 | 304 | 555 | |

| 30 | 349 | 635 | |

| 32 | 397 | 725 | |

| 34 | 429 | 805 | |

| 36 | 497 | 900 | |

| 38 | 556 | 1010 |

Certification

Our rope certification service is available upon request to provide you with peace of mind and confidence in your equipment. Our team of experts will perform a comprehensive analysis of each rope, using the latest testing equipment and techniques to evaluate its strength, durability, and overall suitability for use. This rigorous process will help you avoid potential problems and ensure the safe and reliable operation of your equipment. We can help you meet the various regulations and standards that apply to your equipment and provide you with the assurance that your equipment is up to the task. With our rope certification service available upon request, you can rest easy knowing that your equipment is safe, reliable, and optimized for performance.