6x36ws

Description

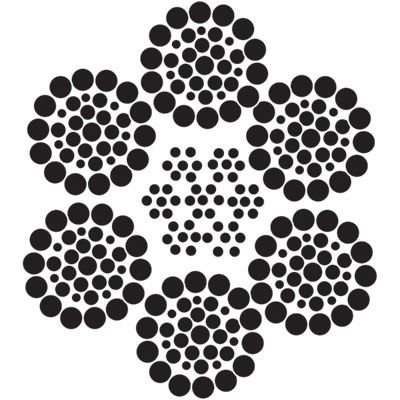

A steel wire rope with a 6x36WS construction is a durable and versatile lifting and hoisting solution designed for various industrial applications. The “6x36WS” designation indicates the specific configuration of the wire strands within the rope.

The “6×36” classification means that the rope is constructed with six main strands, each consisting of multiple smaller wires. This design enhances flexibility and resistance to bending fatigue, making it suitable for applications where the rope needs to navigate pulleys or drums.

The “WS” stands for Warrington-Seale construction, which is a common design for wire ropes. In a 6x36WS rope, the Warrington-Seale construction provides a good balance between strength and flexibility. The outer strands have larger outer wires, offering increased resistance to abrasion, while the inner strands consist of smaller wires, contributing to flexibility.

This steel wire rope is known for its robustness, corrosion resistance, and longevity, making it ideal for tasks such as lifting heavy loads in construction, mining, maritime, and other industrial settings. Its design ensures reliable performance under demanding conditions, making it a trusted choice for various rigging and lifting applications.

Specifications

TEHO SPECIFICATIONS

Weight: ISO Standard

MBL: ISO Standard

Tensile strength: 1960

Lay: Ordinary/ Regular lay

Lubrication: A-1 up to 24mm, A-2 26mm up to 42mm

| Standard | Nominal rope diameter mm | Approximate nominal length mass kg/100 m | Approximate nominal length mass kg/100 m | Minimum breaking force kN (1960 N/mm²) | Minimum breaking force kN (1960 N/mm²) |

| ISO | Fibre core | Steel core | Fibre core | Steel core | |

| 8 | 23.5 | 26.2 | 41.4 | 44.7 | |

| 9 | 29.7 | 33.1 | 52.4 | 56.5 | |

| 10 | 36.7 | 40.9 | 64.7 | 69.8 | |

| 11 | 44.4 | 49.5 | 78.3 | 84.4 | |

| 12 | 52.8 | 58.9 | 93.1 | 100 | |

| 13 | 62 | 69.1 | 109 | 118 | |

| 14 | 71.9 | 80.2 | 127 | 137 | |

| 16 | 94 | 105 | 166 | 179 | |

| 18 | 119 | 133 | 210 | 226 | |

| 20 | 147 | 164 | 259 | 279 | |

| 22 | 178 | 198 | 313 | 338 | |

| 24 | 211 | 236 | 373 | 402 | |

| 26 | 248 | 276 | 437 | 472 | |

| 28 | 288 | 321 | 507 | 547 | |

| 32 | 376 | 419 | 662 | 715 | |

| 36 | 476 | 530 | 838 | 904 | |

| 40 | 654 | 654 | 1040 | 1120 | |

| 44 | 711 | 792 | 1250 | 1350 | |

| 48 | 846 | 942 | 1490 | 1610 | |

| 52 | 992 | 1110 | 1750 | 1890 | |

| 56 | 1150 | 1280 | 2030 | 2190 | |

| 60 | 1320 | 1470 | 2330 | 2510 |

Certification

Our rope certification service is available upon request to provide you with peace of mind and confidence in your equipment. Our team of experts will perform a comprehensive analysis of each rope, using the latest testing equipment and techniques to evaluate its strength, durability, and overall suitability for use. This rigorous process will help you avoid potential problems and ensure the safe and reliable operation of your equipment. We can help you meet the various regulations and standards that apply to your equipment and provide you with the assurance that your equipment is up to the task. With our rope certification service available upon request, you can rest easy knowing that your equipment is safe, reliable, and optimized for performance.