The characteristics of each fiber rope are governed primarily by the material properties, which may be enhanced or moderated during the production process. However, rope selection is ultimately a balancing act between the characteristics of the material, the rope construction, vessel requirements, operating conditions, environmental and safety concerns and of course, cost.

Our MAGNARO® range of fiber ropes is the result of product optimization in view of production efficiency, price competitiveness and market requirements.

All MAGNARO® fiber ropes are produced in accordance with OCIMF Mooring Equipment Guidelines 3rd Edition (MEG3) and/or 4th Edition (MEG4) and can be certified by third party class societies such as LRS, DNV, GL, ABS or NK.

-

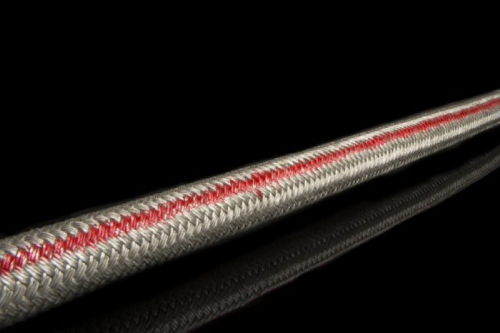

The MAGNARO®-Twaron® Plus rope is a custom-made mooring rope which is mainly selected to perform in very hot areas of the world. Conventional high performance ropes significantly lose strength around 50C and thus can be a health and safety breach in a mooring configuration. The The MAGNARO® Aramid ropes can withstand temperatures up to 427° C.

The MAGNARO®-Twaron® Plus rope is a custom-made mooring rope which is mainly selected to perform in very hot areas of the world. Conventional high performance ropes significantly lose strength around 50C and thus can be a health and safety breach in a mooring configuration. The The MAGNARO® Aramid ropes can withstand temperatures up to 427° C. -

Nylon was the world's first true synthetic textile fiber. Our MAGNARO®-Nylon mooring rope can be used for all purposes and are produced according to the latest EN and ISO standards. It combines high (dry) strength and excellent abrasion resistance. Its high elasticity makes the rope very suitable as a mooring tail.

Nylon was the world's first true synthetic textile fiber. Our MAGNARO®-Nylon mooring rope can be used for all purposes and are produced according to the latest EN and ISO standards. It combines high (dry) strength and excellent abrasion resistance. Its high elasticity makes the rope very suitable as a mooring tail. -

HMPE (High-modulus polyethylene) fibers are produced by gel-spinning ultra-high molecular weight polyethylene (UHMWPE). It has a very low coefficient of friction and is extremely resistant to abrasion. The strength is higher than that of conventional steel wire rope and the corresponding weight is up to 7 times lower. Its better handling characteristics, buoyancy and increased safety (no lash back) are especially appreciated in towing and mooring applications.

HMPE (High-modulus polyethylene) fibers are produced by gel-spinning ultra-high molecular weight polyethylene (UHMWPE). It has a very low coefficient of friction and is extremely resistant to abrasion. The strength is higher than that of conventional steel wire rope and the corresponding weight is up to 7 times lower. Its better handling characteristics, buoyancy and increased safety (no lash back) are especially appreciated in towing and mooring applications. -

HMPE (High-modulus polyethylene) fibers are produced by gel-spinning ultra-high molecular weight polyethylene (UHMWPE). It has an extremely low coefficient of friction and is extremely resistant to abrasion. The strength is higher than that of conventional steel wire rope and the corresponding weight is up to 7 times lower. Its better handling characteristics, buoyancy and increased safety (no lash back) are especially appreciated in towing and mooring applications.

HMPE (High-modulus polyethylene) fibers are produced by gel-spinning ultra-high molecular weight polyethylene (UHMWPE). It has an extremely low coefficient of friction and is extremely resistant to abrasion. The strength is higher than that of conventional steel wire rope and the corresponding weight is up to 7 times lower. Its better handling characteristics, buoyancy and increased safety (no lash back) are especially appreciated in towing and mooring applications. -

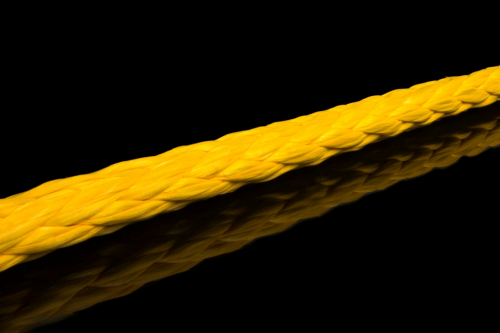

MAGNARO® Float is a mixed or composite rope of high tenacity polyolefin and high performance polyester. A special marine finish is applied to further increase the wear resistance in a marine environment. The rope offers very good abrasion resistance and very high strength. Its buoyancy and excellent handling properties make it the ideal mooring rope for all types of ships.

MAGNARO® Float is a mixed or composite rope of high tenacity polyolefin and high performance polyester. A special marine finish is applied to further increase the wear resistance in a marine environment. The rope offers very good abrasion resistance and very high strength. Its buoyancy and excellent handling properties make it the ideal mooring rope for all types of ships. -

MAGNARO®-Flex is a mixed or composite rope of high tenacity polyolefin and high performance polyester and is one of the best and durable ropes available for mooring and towing purposes. A special marine finish is applied to further increase its wear resistance in the marine environment. Its excellent fatigue characteristics and abrasion resistance, combined with very high strength and smaller diameter, makes it the preferred rope for many ship owners and ship managers.

MAGNARO®-Flex is a mixed or composite rope of high tenacity polyolefin and high performance polyester and is one of the best and durable ropes available for mooring and towing purposes. A special marine finish is applied to further increase its wear resistance in the marine environment. Its excellent fatigue characteristics and abrasion resistance, combined with very high strength and smaller diameter, makes it the preferred rope for many ship owners and ship managers. -

Our MAGNARO®-6 is a 6 strand cross-laid nylon rope, whereby mono-filaments and multi-filaments are combined in the strands. The mono-filaments give the rope excellent abrasion resistance and dimensional stability, resulting in an excellent behavior on the winch drum. Its robust construction maintains shape under extreme tension. The rope is easier to handle than wire and easy to splice.

Our MAGNARO®-6 is a 6 strand cross-laid nylon rope, whereby mono-filaments and multi-filaments are combined in the strands. The mono-filaments give the rope excellent abrasion resistance and dimensional stability, resulting in an excellent behavior on the winch drum. Its robust construction maintains shape under extreme tension. The rope is easier to handle than wire and easy to splice.